1-800-355-2335 |

Mon-Fri: 7:30am - 4pm EST |

Contact Us

Fencing Tools

From Homo Erectus to Fence Erectus, we've assembled here the finest fencing tools known to man after nearly 3 million years of tool making. So stand proudly upright, tool in hand, and separate yourself from the rest of the animal kingdom!

From levers to pulleys - cranks, gears, and cams, there’s no better (or faster) way to assemble a fence. See for yourself what it’s like to multiply force and master gravity.

Just be forewarned, most of these tools aren’t your average father-in-law’s tools. Most of these we’ve personally used for decades and still use today (the same ones). Built tough, built to last, and built to save you time!

$351.69 - $390.77

Malco ProductsHRP5 Commerial Grade Hog Ring Pliers with Magazine

#HRP5EV

Add to cart

$121.97

$107.56 - $159.26

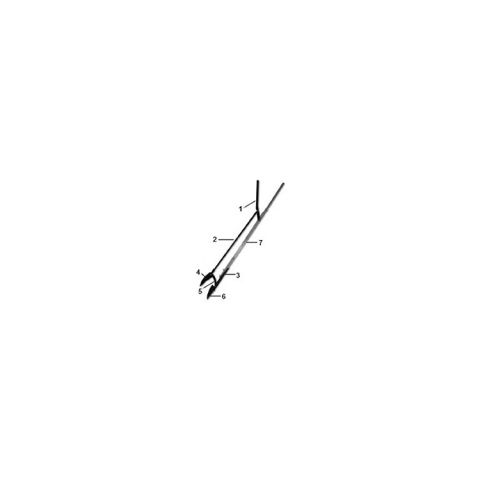

SeymourAdjustable Iwan Post Hole Augers - Bores Post Holes 4"-5"- 6" diameter holes

#SEY-AU-P

View More

$36.45 - $40.50

Pull'RMaasdam - The Dog - Cable Grip(pull max. 1/4" wire or cable)

#M8050-S

Add to cart