Jerith Patriot Ornamental Wire Fence System

Shop: Jerith Patriot Wire Fence

Read More: Ornamental Fence Overview

Jerith has united the warmth and old-world charm of wrought iron fence with the inexpensive functionality of chain link in our Patriot Ornamental Wire Fence System! This remarkable product satisfies the demand for an elegant, strong, and durable metal fence at a cost comparable to chain link. By using visually appealing mesh patterns and adding horizontal rails for a truly ornamental appearance, we have created an attractive metal fence that is unlike any other.

This remarkable fence was honored at the American Business Awards as winner of the "Best New Product or Service" category. The elegant "Stevie" trophy, as it is known, was presented to Jerith at a ceremony in New York City before 500 attendees. Hailed as "the business world's own Oscars" by the New York Post, the American Business Awards are the first national business awards program honoring great performances in the workplace.

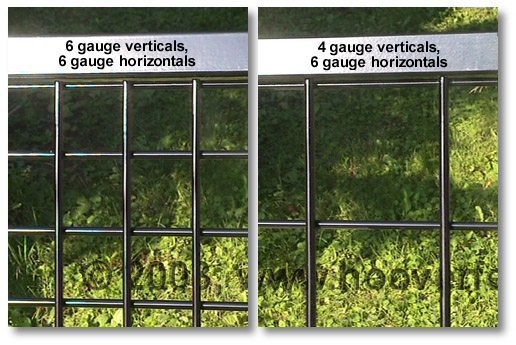

Because our mesh uses heavy 4 and 6 gauge wires that are welded at each intersection, we achieve superior strength in this metal fence. The tubular steel rails welded above and below the wire mesh increase Patriot Fence's strength and rigidity even further. Tests performed on a section of Patriot Fence determined that this design can withstand a 550 pound load without any permanent deformation.

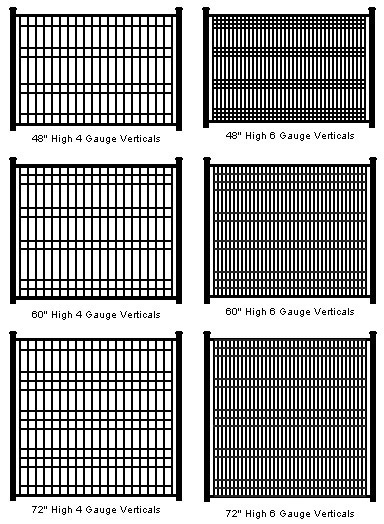

The unique, patented mesh design gives Patriot Fence the "style" that chain link and other welded wire products lack. Vertical wires are either spaced 3-1/2" apart to create a more open appearance similar to the pickets in a wrought iron fence, or 1-3/4" on center for extra security. This narrow wire spacing is very difficult to climb and meets most building codes for swimming pool fences. Plus, the entire Patriot Fence system is galvanized and powder-coated for outstanding outdoor durability. This combination of features allows us to offer an 8-year warranty on the fence, including its finish. Patriot fence panels are 6' wide and are available in 4, 5, and 6 foot heights. They can also be stacked on top of each other to reach as high as 12 feet tall.

However, the best feature of the Patriot Fence is that it is priced just slightly more than vinyl-coated chain link, but much lower than other galvanized steel ornamental fences. Patriot Ornamental Wire Fence is clearly THE elegant, attractive and affordable metal fence alternative!

Jerith Patriot™ Brochure (PDF)

About The Sections

Patriot™ wire fence sections are available in 4', 5' and 6' heights. Horizontals wire spacing will vary with height, spaced to provide style differences but no farther apart than would allow for substantial rigidity of vertical wires. Pattern will be based on gauge of vertical wires. The 4 gauge fabric has a 3.5" spacing on the vertical wires. The 6 gauge fabric has 1-3/4" spacing on the vertical wires.

Section Features:

- Sections are all steel construction.

- Post spacing is 72" on center with 2" posts.

- Wires welded at each intersection - much stronger than chain link.

- Fence sections shipped fully assembled.

- FencCoat™ powder coating on all components, black only.

- Fence height is installed height with 2" ground clearance.

- Heavy 4 and 6 gauge wires - more durable than other security fences.

- Performance load tested - surpasses strict building codes.

- 1-3/4" security spacing on 6 gauge styles - virtually unclimbable - pool safe in all heights.

- 100% Made In America.

About the Posts

- Caps and brackets of aluminum or zinc.

- Posts include flat caps and mounting hardware.

About the Gates

Jerith Patriot Gates are sold as gate kits only. You must purchase the sections separately to build your own gates using the kits.

Single Gate kit consists of a 2 gate uprights (sides), set of self-closing hinges and a self latching gate latch.

Double gate kit consists of 4 gate uprights (sides), 2 sets of self-closing hinges, self latching gate latch, and 1 drop rod.

Gates can be assembled up to 6' wide, 12' wide on double gates.

Gates smaller than 6' wide require cutting fence section to desired width.

System Specifications:

| Specifications | |

|---|---|

| Available Colors: | Black Only |

| Vertical Wire Spacing: | 1-3/4" for 6 Gauge; 3-1/2" for 4 Gauge |

| Post Size / Wall Thickness: | 2" Square / 16 Gauge (0.065") |

| Panel Width: | 72" Post Centers with 2" Posts (Actual Width 70") |

| Raking (Out of Sq. for Slopes): | None - Welded Panels Must Be Stepped |

| Available Heights: | 4', 5', and 6' |

| Horizontal Wire Size: | 6 Gauge (0.192") for All Styles |

| Vertical Wire Size: | 4 Gauge (0.225") or 6 Gauge (0.192") |

| Rail Size / Wall Thickness: | 1" Square / 18 Gauge (0.49") |

| Weight Supported: | 550 lbs. Vertically; 225 lbs Horizontally at Midspan for All Styles |

| Post Caps & Rail Ends: | Aluminum or Zinc (Included with Posts) |

| Fasteners: | Stainless Steel (Included with Posts) |

| Paint: | FencCoat™ Powder-Coating - 8 Year Manufacturer's Warranty |

| Gate Hardware: | Self-Closing Hinges and Latch Included with All Gates; Double Gates Also Include 1 Drop Rod |