Cantilever Slide Gate System Overview

Shop: Cantilever Slide Gates | Cantilever Slide Gate Hardware | Cantilever Slide Gate Kits

Cantilever Slide Gate Theory:

The term, cantilever slide gate, may refer to any number of gates, from ornamental picket styles to functional chain link styles, from those that require cantilever rollers to those requiring gate tracks and trolleys. All cantilever slide gates will share certain characteristics which differentiate themselves from other types of slide gates. Cantilever slide gates are unique from other types of slide gates in their construction, hardware choices, and design.

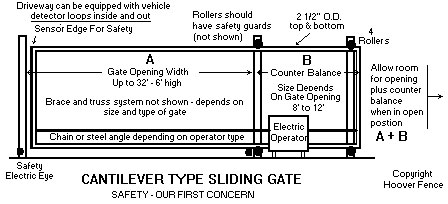

Cantilever slide gates are built larger than the gate opening they are designed to close, often as much as 50% larger than their respective openings. The idea here is to hang the gate on two or more mounting posts and have the gate suspend off these mounting posts into the gate opening to close. In general, no part of the gate comes in contact with the ground directly, or indirectly with any type of wheel. Instead, these slide gates 'cantilever' to close the opening. Cantilever construction allows for overhanging structures without external bracing. It is key that cantilever gate frame be constructed properly to help withstand the forces of gravity and wind. Intricate diagonal bracing and trusses are usually strategically welded in place to help prevent gate sag.

Other types of slide gate systems may have a leading edge wheel installed on the latch side of the gate. These leading edge type wheels either roll directly on the ground, or on a track installed across the driveway or gate opening. Care must be taken to assure the gate opening or driveway is kept perfectly clear of debris or wheels will meet obstructions. Gates which slide on a track imbedded on the ground are often referred to as V-Track gates. Essentially a piece of inverted angle iron is bolted down to concrete and a special v-groove wheel rides it. Gates which have a rubber or pneumatic wheel to roll over the ground are simply Rolling Gates. V-Track gates are popular in southern regions where snow and ice are rare. V-Track gates are often automated with gate operators. Rolling gates on the other hand are popular in northern and southern regions. Both these styles can be appealing as they often will not require a counterbalance which can be as large as 50% more than the gate opening. Automating a slide gate requires the gate slide perfectly in both directions and be installed level. Although this is often easiest to accomplish by installing a cantilever gate, v-track gates and rolling gates can also carefully be automated. Again, automating a slide gate requires the gate slide perfectly in both directions! Possible obstructions to leading edge wheels such as snow, ice, and other debris will cause gate operator failure. Gates which do not stay on their tracks can be extremely dangerous when opened and closed manually, and especially with a gate opener.

Advantages of cantilever slide gates over other styles are numerous:

1. Cantilever gates may use less space than a swing gate system. Single cantilever gates move in one direction, often directly parallel to an existing fence line. This efficient use of space makes a cantilever gate an ideal choice when designing a property's perimeter fence and security system.

2. Cantilever gates may be easier to safeguard than swing gates when automating. Safety devices are strongly recommended, if not required, when automating a gate. Such safety devices may include safety photobeams, safety edges, and loops and loop detectors. Safety devices are designed and installed to protect against the gate closing on a vehicle. Due to the linear movement of a sliding cantilever gate, the path of the gate is limited in comparison to a swing gate which swings in an arc approximately 90 degrees.

3. Cantilever gates may be less expensive to automate than swing gates. In some instances, when a double swing gate and a single cantilever gate is to be considered, a single cantilever gate will be less expensive to automate since it requires only one gate operator instead of two.

4. Cantilever gates may require less maintenance than swing gates. Cantilever gates may be installed with nylon cantilever rollers with sealed bearings and nylon roller covers. These rollers do not require greasing and the nylon roller itself and cover will not rust. Further, cantilever rollers will install to posts with bolts which are easy to adjust at a later date if necessary. The brackets which typically connect a gate operator to the gate also are usually installed with bolts that will be easy to adjust later. Conversely, swing gates often have hinges which require repeated greasing. These hinges will also often be welded to the gate post and gate making them difficult to adjust if necessary. Lastly, consider snow removal in northern locations. The single path a cantilever gate travels will often be easier to keep clean of obstructions compared with a swing gate and it's wide swing.

5. Cantilever gates are aesthically appealing. The smart appearance, efficient design, and craftsmanship in a cantilever gate is sure to impress owners, visitors, and customers visiting the property.

Cantilever Slide Gate Practice:

Typically two or more galvanized steel posts are set to support the weight of the gate and serve as mounting posts. Gate posts may be round or square. Gates may be built as much as 50% more than the gate opening size to provide a counterbalance, or cantilever for the gate opening portion. Gate frames may be round or square. Gates may be constructed of aluminum or steel - both are normally welded construction. Professional gate construction is highly recommended as gate frames themselves often serve as the track, providing a smooth even surface for gates to open and close with.

Gates are often stretched with chain link across a portion, or all of the frame. Gates which are automated should have mesh stretched across the entire surface for safety reasons and to comply with ASTM and UL-325 standards.

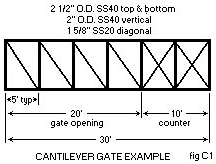

Steel Cantilever Gates - Steel Cantilever Gates are typically constructed with galvanized round tubing. Top and bottom horizontals rails are often 2-1/2" O.D. (2-3/8" actual) tubing in Sch40 or HF40 grades. 2" O.D. (1-7/8" actual) serve as vertical braces, and 1-5/8" O.D. diagonal bracing is welded in place to help prevent gate sag. Domestically made steel or nylon cantilever gate rollers are mounted to the mounting posts, normally two at top and two at bottom. Import cantilever rollers are also plentiful in both steel and nylon and are generally less expensive. Be sure to use cantilever gate roller covers on all rollers for safety and to protect pinch points. Gate is 'sandwiched' in-between the top and bottom rollers and slides to open and close. Cantilever gate rollers typically all have a galvanized chassis to prevent rust. Rollers themselves are available in galvanized steel or nylon. Both are quality rollers which can provide years of uninterrupted service. An assortment of padlockable cantilever gate latches are available. Some are designed specifically as automated slide gates latches. Steel cantilever gates can be made to close gate openings 30' wide plus! 60' wide plus openings can be closed using a double cantilever gate.

Aluminum Cantilever Gates - Internal Track Aluminum Slide Gates are often made entirely of aluminum. A heavy duty aluminum gate track is welded to, or is part of the gate frame itself. Hoover Fence offers aluminum slide gates built to close 30' wide gate openings made with a single gate track. A 60' wide opening can be closed using a double gate. We offer double track aluminum slide gates for gate openings up to 40' wide, 80' wide doubles. Custom box frame gates are available for openings larger than 40', but less than 60'. Although top track gates are more popular, bottom track and bottom track gate components are also available. Gate track and gate frame slides to open and close across two or more fixed gate trucks. Gate trolleys are secured to galvanized steel mounting posts with galvanized steel truck hanger brackets.

Slide Gate Counter Balance:

Counterbalance should be approximately 1/2 the length of the gate opening. Minimum counter balance should be 4' long. If an automatic operator is to be installed, the counter balance may need to be longer so the operator can 'pull' the gate shut by the rear of the counter balance. Always choose the operator and gate before construction begins.

Post Sizes:

Generally steel chain link cantilever slide gates require 3" O.D. roller posts for widths up to 10' opening size. Use 4" O.D. posts up to 20' and 6-5/8" O.D. posts up to 32'. These specifications are for 6' high gates and shorter. For taller gates increase post sizes at each step and use 8-5/8" O.D. posts for 32' gates. We use mostly 4" OD steel posts for our aluminum slide gates.

Concrete Footers:

18" diameter x 42" deep is recommended for 3-4" posts, 24" diameter x 42" for 6-5/8" O.D. posts and 30" diameter x 48" for 8-5/8" O.D. posts. Increase bottom diameters 6"; creating a bell-shaped hole. The up and down stress with these type gates will 'work' even the largest posts out of the ground. Poor soil conditions, such as sand, will require larger footers. Always consult local building codes or practices prior to beginning any construction project. Call 811 prior to excavating post hole footers.

© 2010, All Rights Reserved

Specifications & Information Subject to Change without Notice