SHUT IT! The 100 Year BadAss Hinge

Item # CI3520Details

Details

Shut It Sell Sheet | D&D Technologies Catalog

Shut It Sell Sheet | D&D Technologies Catalog

The 100 Year BadAss Hinge (CI3520)

SHUT IT's biggest and baddest gate hinge is so durable our standard lifetime warranty does not do it justice. Therefore, the Smartasses at SHUT IT! decided to warranty the product for 100 years! The Hundred Year Hinge uses the unique SHUT IT bushing design with upgraded hardware for additional strength and longevity.

The 100 Year BadAss Hinges feature high-temperature sealed bearings which not only allow for the smooth operation you would expect from these hinges, but also allows the hinges to be welded, and then powder-coated with your custom swing gate.

- The 100 Year BadAss Hinge Features:

- 100 Year Warranty

- Three Sealed Maintenance Free Bearings (no greasing)

- High-temp Bearings, Safe to Powder-Coat

- Thicker Bracket and Higher-Tensile Shaft

- Heavy-Duty Yoke.

- Zinc Plated

- Adjustable Yoke For Perfect Installations

- Ideal For Both Round and Flat Post Installations

- Load rating per gate: 3,000 lb (1,360kg)

- Maximum gate weight: 1,500 lb (680kg)

- Weld-on Installation

Specifications

Specifications

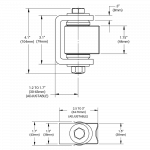

The 100 Year BadAss Hinge Specifications

| SKU | Finish | Fixing | Gap Variance | Bracket | Body | Height | Weight |

|---|---|---|---|---|---|---|---|

| CI3520 | Zinc | Weld | 2-13/32 - 2-29/32" (64-76mm) | Steel | Steel | 4-3/32" (104mm) | 3.5 lb (1.6kg) |

| Product Code | CI3520 |

|---|---|

| Gate Application | Pedestrian Gate, Driveway Gate - Double, Driveway Gate - Single, Pet Gate, Playground Gate, Public/Commercial Gate, Automated/Electric Gate, Security Gate, Privacy Gate |

| Gate Type | Non Self-Closing |

| Gate Material | Steel/Ornamental Iron |

| Approx Gate Size | 6ft W x 8ft H (1.5m x 2m) |

| Gate Frame/Post Shape | Square-to-Square, Square-to-Round |

| Min Post Size | 1-1/2"+ (38mm) |

| Ideal Gate Gap | 2-1/2-3" (64-76mm) |

| Fixing Method | Weld-On |

| Color/Finish | Zinc |

Warranty

Warranty

100 Year Warranty component replacement guarantee (5 years for bearings).

FAQ

FAQ

Warning: Hinges will be severely damaged if electrical welding current is not properly grounded resulting in the Warranty being voided.

For welding stainless steel hinges to mild steel gates and posts we recommend using type 309 (23 12L to BS EN 12072) welding rods or wire. This is should help avoid cracking in the weld dilution zone that can be a problem if normal rods or filler are used.

Unprotected welds subject to aggressive environments such as immersion in seawater could result in sacrificial corrosion to the less noble carbon steel part. However, post-weld surface coating repair would normally be needed for the carbon steel to ‘restore’ the corrosion protection.

If this re-coating/painting is allowed to lap over onto the weld bead then the joint should not be at risk to bimetallic corrosion in any environment so long as the coating is sound. Ideally the weld bead should be covered so that only the ‘parent’ stainless steel is exposed. This ensures that galvanic corrosion cells cannot be set up across the joint, where there is a composition ‘gradient.’

Reviews

Reviews

There are no reviews yet. Be the first to Write a Review (requires login).

Shipping

Shipping

Shipping Expense Disclaimer: All orders are subject to confirmation. Additional shipping expenses, although rare, may apply due to weight, size, location, and/or other variables. Should your order require additional funds to cover the transportation of goods, you will be contacted prior to order processing for approval.