SHUT IT! The Self Closing BadAss Hinge Set

Item # CI3850Details

Details

Shut It Sell Sheet | D&D Technologies Catalog

Shut It Sell Sheet | D&D Technologies Catalog

The Self Closing BadAss Hinge Set (CI3850)

Finally, an easy to install heavy duty self closing hinge! SHUT-IT is excited to release the newest in the line of BadAss Hinges - The Self-Closing BadAss Hinge Set. With the BadAss Self-Closing Hinge you no longer need a separate closer for jobs that require a self closing gate. The closer is built into the hinge! Get the benefits of the best heavy duty gate hinges and a reliable closer in one package. Save hundreds on poorly designed gate closers and hydraulic door closers that are adapted to gate systems. Ideal for panic bar installations.

- The Self-Closing BadAss Hinge Set Features:

- Two Sealed Maintenance Free Bearings (no greasing)

- Limited Lifetime Warranty

- Zinc Plated

- Adjustable Yoke For Perfect Installations

- Ideal For Both Round and Flat Post Installations

- Self Closing Torsion Spring

- 5 tension-adjustment settings on self-closing hinge

- Load rating per gate: 2,000 lb (900kg)

- Self-closing Maximum Gate Weight: 300 lb (130kg)

- Patent Pending

- Weld-on Installation

- Sold as a set - Set includes one self-closing hinge and one CI3000 (The Original BadAss Hinge).

- Easy to install, heavy duty self-closing hinge

- Gate swings from -5° to 110°

- Ideal for panic bar installations

- Closer is built into the hinge (unable to powder-coat)

Specifications

Specifications

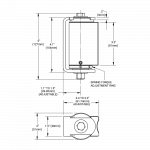

The Self Closing BadAss Hinge Set Specifications

| SKU | Finish | Fixing | Gap Variance | Bracket | Body | Height | Weight |

|---|---|---|---|---|---|---|---|

| CI3850 | Zinc | Weld | 2-13/32 - 2-29/32" (61-74mm) | Steel | Steel | 5" (127mm) | 5.5 lb (2.5kg) |

| Product Code | CI3850 |

|---|---|

| Gate Application | Pedestrian Gate, Driveway Gate - Double, Driveway Gate - Single, Pet Gate, Playground Gate, Public/Commercial Gate, Automated/Electric Gate, Security Gate, Privacy Gate |

| Gate Type | Self-Closing |

| Gate Material | Steel/Ornamental Iron |

| Self-Closing Gate Weight | Up to 300lb (130kg) |

| Approx Gate Size | 6ft W x 8ft H (1.5m x 2m) |

| Gate Frame/Post Shape | Square-to-Square, Square-to-Round |

| Min Post Size | 1-1/2"+ (38mm) |

| Ideal Gate Gap | 2-1/2 - 3" (61-74mm) |

| Fixing Method | Weld-On |

| Color/Finish | Zinc |

Warranty

Warranty

Lifetime component replacement guarantee (5 years for bearings).

FAQ

FAQ

Warning: Hinges will be severely damaged if electrical welding current is not properly grounded resulting in the Warranty being voided.

For welding stainless steel hinges to mild steel gates and posts we recommend using type 309 (23 12L to BS EN 12072) welding rods or wire. This is should help avoid cracking in the weld dilution zone that can be a problem if normal rods or filler are used.

Unprotected welds subject to aggressive environments such as immersion in seawater could result in sacrificial corrosion to the less noble carbon steel part. However, post-weld surface coating repair would normally be needed for the carbon steel to ‘restore’ the corrosion protection.

If this re-coating/painting is allowed to lap over onto the weld bead then the joint should not be at risk to bimetallic corrosion in any environment so long as the coating is sound. Ideally the weld bead should be covered so that only the ‘parent’ stainless steel is exposed. This ensures that galvanic corrosion cells cannot be set up across the joint, where there is a composition ‘gradient.’

Reviews

Reviews

Average Customer Rating:

(6 Reviews)

Write a Review (requires login)

(6 Reviews)

Write a Review (requires login)

Great experience through the full

Great experience through the full process, easy payment methods, fast shipping... untill now, I have had no need to contact customer support for any reazon..... Great Job!!!!

Really good experiences through all..

Really good experiences through all this time, very good service and fast shipping!!!

Great Customer Service .

Great Customer Service .

Easy access

Easy access, prompt delivery, quality product

Well done Hoover Fence Co.

Once again, the online order process is very easy and the delivery was as expected. Well done Hoover Fence Co., we’ll be back.

Shipping

Shipping

Shipping Expense Disclaimer: All orders are subject to confirmation. Additional shipping expenses, although rare, may apply due to weight, size, location, and/or other variables. Should your order require additional funds to cover the transportation of goods, you will be contacted prior to order processing for approval.