Chain Link Fence System Overview

Shop: Chain Link Fence Catalog

Chain Link Fence is a component based fencing system that is the most widely used style in the industry. There are a few basic components that make up a chain link fence, and each have special fittings that are used. This guide is broken down into those basic components, and include information that describes the basic parts, how they are used, and how to order them. As always, there are exceptions to the rules but this should cover the majority of applications.

Jump to Preferred Section:

Chain Link Fabric | Chain Link Framework | Post Fittings | Chain Link Gates | Gate Fittings | Wires/Ties

General Overview:

Hoover Fence Company's forty-plus years in the fence business is unparalleled. Our fence experience ranges from all phases of residential fence construction to the most difficult and specification-based industrial security fencing applications, including professional baseball stadiums, stringent nuclear plants, and high security airport fence jobs. We've fenced in buildings, inside of buildings, on roofs, in fresh and saltwater; we've even fenced in lions, tigers, and bears! Our full fabrication shop, experienced staff, wide range of standard and specialty fence parts inventory, and long-standing relationships with top fence manufacturers, makes Hoover Fence an ideal supplier for all fencing projects.

With some of our helpful fence tips, free fence calculators and estimators, and free and very popular "How To Install a Chain Link Fence Manual", there is no job too small, or too large. With assistance from the Hoover Fence Team, all phases of your project will either be handled directly or reviewed by a Certified Fence Professional educated and experienced in fence specifications and quality fence materials. Don't be fooled by inexpensive fence materials sold through big-box stores; these materials are usually not worth the effort to install and will not stand the test of time. We offer free fence technical support before, during, and after the sale.

Chain link fence is most commonly available galvanized which is silver in color. We also carry colored chain link fence fabric, framework (posts and rail), colored fence fittings, gates (swing and slide), and gate hardware for all fencing applications from standard residential to light commercial, to heavy commercial and industrial fence applications.

Colored fence fittings and chain link framework (posts and rails) are either powder coated, or coated in a heavy vinyl coated (PVC) material in standard colors such as black, dark brown, and dark green. White is also available as special order fencing. It is not uncommon to combine the two and stretch a vinyl coated chain link fabric on a galvanized frame. All aluminum chain link fabric, aluminum tubing, and aluminum chain link fittings and gates are also available for special applications and is preferred by many near saltwater.

Specialty fence product or fabrication or installation need? Contact us for a custom quote.

Chain Link Fence Guides:

- Chain Link Fence FAQ's

- Guide to Pool Safe Fences

- How to Prepare Fence Layout Drawing

- How to Install Chain Link Fence

- How to Bias Cut Chain Link Fence

- How to Brace and Truss Chain Link Fence

- Chain Link Fence Specifications

- Residential vs. Commercial Chain Link Guide

- Chain Link Fence Windload Guide (PDF)

Chain Link Fabric:

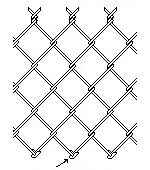

Chain link fabric is typically sold in 50' rolls. We will cut rolls to exact size for local deliveries and pick-ups only. Deliveries made out of state will receive full rolls. We recommend ordering a few extra feet than needed. When more than 50' of fence is needed for a stretch, rolls can be woven together easily. Chain link is easily cut to size by removing one link.

About gauges: The smaller the number, the heavier the fabric; henceforth 9ga. is heavier than 11ga.. We recommend 11ga. for residential jobs and 9ga. for commercial jobs. Heavier gauges are not only stronger, but have a better finish; The heavier the gauge the longer it may be 'hot-dip galvanized' to prevent rust and corrosion.

Vinyl coated chain link is sold by the finish gauge. 9 ga. chain link vinyl coated actually has a thinner inner steel wire. It is considered 9 gauge once it has been coated, although the inner steel wire is nearest 11 ga.

Barbed End

Knuckled End

Mesh Size

Measured Diagonally

About knuckles and barbs: Fence fabric is available two ways. Chain link fabric under 72" high is available with knuckles on both ends. Chain link fabric 72" and taller comes with knuckles on one end and barbs on the other end. (two barbs are formed when the chain link is twisted at one end).

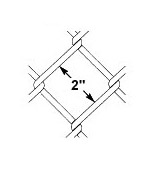

About mesh size: The galvanized fabric mesh for 11-1/2 gauge measures 2-1/4". The 11, 9, and 6 gauge galvanized mesh measures 2". Mesh size is the measured distance between two parallel sides.

Hoover Fence Company carries two types of vinyl coated chain link fabric. One has 2" mesh, the other has a tight 1-1/4" mesh. The 1-1/4" mesh fabric is specified frequently for pool safety reasons and to help prevent climbing of the fence.

Aluminized Chain Link Fabric:

Shop: Aluminized Fabric

This fabric has 0.40 aluminum on 9 gauge. Meets ASTM A-491; AASHTO M181, Type II; Federal Specifications RR-F-00191/1D, Type II

Gauges - 11 Gauge, 9 Gauge, and 6 Gauge

Heights - 3', 3-1/2', 4', 5', 6', 7', 8', 10', and 12'

Mesh Size - 1-3/4" and 2"

Aluminum Chain Link Fabric:

Shop: Aluminum Fabric

All aluminum chain link fence is both structural as well as decorative. Its rapid growth in the fence industry is due to such factors as corrosion resistance, lightness, pleasing appearance, and minimum maintenance requirements. Aluminum is becoming increasingly important in such usage as it provides permanent, maintenance free enclosures, and protective barriers in keeping with contemporary design requirements.

A chain link fence of aluminum has a natural, trim beauty that is difficult to attain with other fencing material. The attractiveness lasts, moreover, because of the metal's inherent resistance in harsh industrial and seacoast atmospheres that cause rapid deterioration in most other metals. Since painting is unnecessary, maintenance cost savings over the lifetime of an aluminum chain link fence will more than pay for the initial cost of the fence. This one consideration has become the major factor in the overall cost of a wire fence, as maintenance costs have risen steadily each year.

Aluminum fences are high strength installations and can be relied upon under the hardest usage. They resist strains and impacts, often more satisfactorily than traditional materials. Aluminum fencing is entirely salvageable - fence locations can be changed, if necessary, and all components re-used, even after a fence has been installed for years.

Gauges - 6 Gauge and 9 Gauge

Heights - 3', 3-1/2', 4', 5', 6', 7', 8', 10', and 12'

Mesh Size - 1" and 2"

Galvanized Before Weave (GBW) Chain Link Fabric:

Shop: Galvanized Fabric

This fabric is galvanized before weaving (GBW) with a 1.2 oz. coating. Meets ASTM A 392-96 Class I.

Gauges - 11-1/2 Gauge, 11 Gauge, 9 Gauge, and 6 Gauge

Heights - 3', 3-1/2', 4', 5', 6', 7', 8', 10', and 12'

Mesh Size - 2" and 2-1/4"

Galvanized After Weave (GAW) Chain Link Fabric:

Shop: Galvanized Fabric

This fabric is galvanized after weaving (GAW) with a 1.2 oz. coating. Meets ASTM A 392-96 Class I. We also offer some sizes with a 2.0 oz. galvanized coating. Meets ASTM A 392 Type I (Class II).

Gauges - 11-1/2 Gauge, 11 Gauge, 9 Gauge, and 6 Gauge

Heights - 3', 3-1/2', 4', 5', 6', 7', 8', 10', and 12'

Mesh Size - 1-3/4", 2", and 2-1/4"

Vinyl Coated Chain Link Fabric:

Shop: Vinyl Coated Fabric

What is extruded vinyl? In layman's terms, extruded vinyl. when cut with a knife, can be peeled off like a banana. However, it does not peel easily. That is what makes extruded different then bonded vinyl, which would have to be cut off completely, much like peeling a potato. Bonded costs more than extruded. We do not sell bonded vinyl fabrics.

Gauges - 8 Gauge and 9 Gauge

Heights - 3', 3-1/2', 4', 5', 6', 7', 8', 10', and 12'

Mesh Size - 1-1/4" and 2"

Colors - Black, Brown, Green, and White (Special Order)

Chain Link Framework:

Chain link fence tubing is used for the framework, or 'skeleton' of the fence. Use for all horizontal rails such as toprail, bottom rail, and mid-rails. Use for bracing and gates. Can be purchased in full lengths or as cut posts for your convenience. For best performance, cement all posts in concrete. At a minimum set all terminal posts in cement and drive line posts using a post driver. Line posts that are driven should also have spade post anchors installed to prevent leaning. Another strong alternative to cementing posts is to use Oz-Post.

We offer steel materials in galvanized and color coated options. We also offer an aluminum Sch40.

We Recommend our Residential Grade framework system for residential applications, HF20 Framework for commercial applications, and HF40 Framework for industrial fencing applications.

Residential Guidelines:

Terminal posts for residential chain link fence are typically 2-1/2' longer than the height of fence being installed, i.e. a 6' high fence has 8 1/2' long terminal posts. Line posts are typically 2' longer than the height of fence being installed for residential applications, i.e. a 6' high fence has 8' long line posts. Check your local building codes and practices for proper installation.

Commercial Guidelines:

Terminal posts for chain link fence are typically 36" longer than the height of fence being installed for commercial, i.e. a 6' high fence has 9' long terminal posts. Chain link line posts are typically 2-1/2' longer than the height of fence being installed for commercial, i.e. a 6' high fence has 8'6" long line posts. Check your local building codes and practices for proper installation.

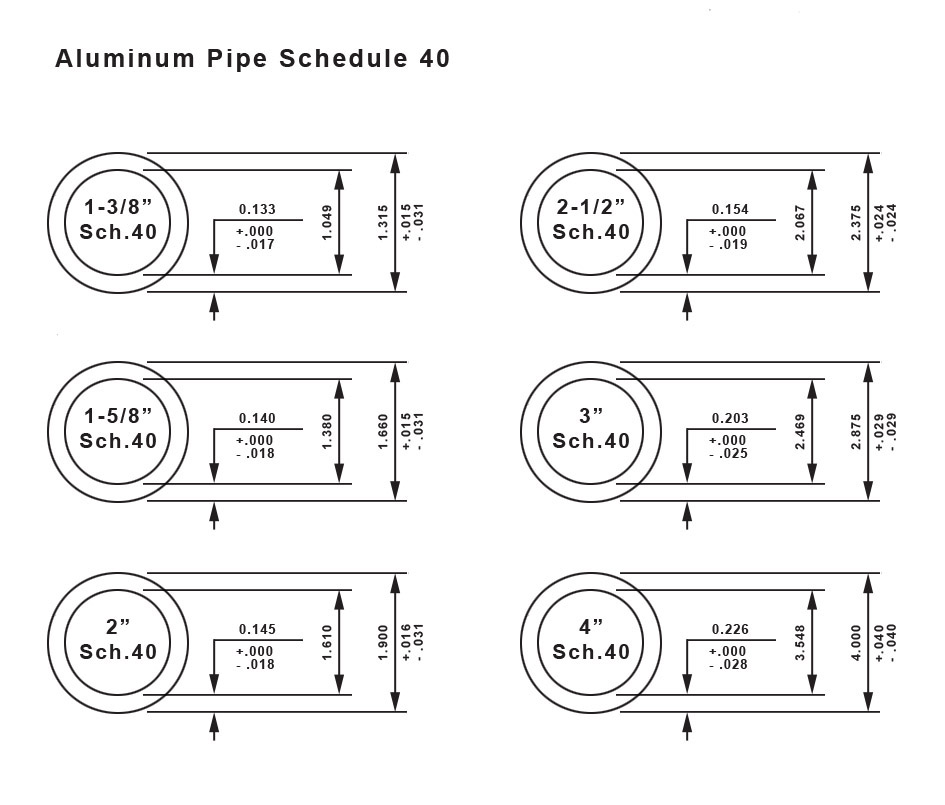

Fence Tubing Sizing Notes:

| Fence Industry | Actual Measurement |

|---|---|

| 1-3/8" O.D. | 1-5/16" Actual (1.315") |

| 1-5/8" O.D. | 1-5/8" Actual (1.660") |

| 2" O.D. | 1-7/8" Actual (1.900") |

| 2-1/2" O.D. | 2-3/8" Actual (2.375") |

| 3" O.D. | 2-7/8" Actual (2.875") |

| 3-1/2" O.D. | 3-1/2" Actual (3.500") |

| 4" O.D. | 4" Actual (4.000") |

| 4-1/2" O.D. | 4-1/2" Actual (4.500") |

| 6-5/8" O.D. | 6-5/8" Actual (6.660") |

| 8-5/8" O.D. | 8-5/8" Actual (8.660") |

Specifications:

SS15®

Allied manufacturers SS15® with high tensile steel is cold formed to a minimum of 50,000 psi yield strength. It is manufactured with their patented in-line continuous triple-coat FLO-COAT™ process.

SS15 fence framework is ideal for a wide variety of light commercial and heavy residential. Such applications include:

- Athletic Enclosures

- Controlled Access Fencing

- Dog Kennels

- Private Parking Lots

- Security Partitions

- Residential Applications with Heavy Snow Load

| Size (O.D.) | Decimal Equivalent | Pipe Wall Thickness | Weight | Section Modulus | Minimum Yield | Bending Moment | Calculated Loads | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | in. | mm | in. | mm | lb./ft. | kg/ft. | in.² | psi | lbs./in. | 10' Free | 4' Cantilever | 6' Cantilever |

| 1-3/8" | 1.315 | 33.40 | 0.072 | 1.83 | 0.96 | 1.43 | 0.0829 | 50,000 | 4,144 | n/a | n/a | n/a |

| 1-5/8" | 1.660 | 42.16 | 0.072 | 1.83 | 1.22 | 1.81 | 0.1367 | 50,000 | 6,837 | 139 | 142 | 95 |

| 2" | 1.900 | 48.26 | 0.072 | 1.83 | 1.41 | 2.09 | 0.1821 | 50,000 | 9,107 | 139 | 190 | 126 |

| 2-1/2" | 2.375 | 60.33 | 0.072 | 1.83 | 1.77 | 2.63 | 0.2912 | 50,000 | 14,559 | 228 | 303 | 202 |

SS20®

Allied manufacturers SS20® with high tensile steel meeting ASTM A 569 and is cold formed to a minimum of 50,000 psi yield strength. It is manufactured with their patented in-line continuous triple-coat FLO-COAT™ process. Allied's SS20® out-performs mill structural pipe both in strength and corrosion resistance. SS20® is 30% stronger and 20% lighter than mill structural pipe.

A uniform application of zinc, chromate, and a clear organic top coat gives SS20® a superior exterior finish. This carefully monitored triple coating results in a smooth, lustrous, and durable surface that provides lasting corrosion resistance in all climates and under the most severe atmospheric conditions.

With a proven performance record, Allied's SS20® continues to be the pipe of choice for the following applications:

- Perimeter fences and security fences

- Fences for sports facilities

- Fences for parks and recreational playgrounds

- Partitions

- Parking lots

- Tool Cribs

- Industrial and residential gates

- Athletic fields

| Size (O.D.) | Decimal Equivalent | Pipe Wall Thickness | Weight | Minimum Yield | Calculated Loads | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| in. | in. | mm | in. | mm | lb./ft. | kg/ft. | psi | 10' Free | 4' Cantilever | 6' Cantilever |

| 1-3/8" | 1.315 | 33.40 | 0.080 | 2.03 | 1.056 | 1.57 | 50,000 | 150 | n/a | n/a |

| 1-5/8" | 1.660 | 42.16 | 0.085 | 2.16 | 1.431 | 2.13 | 50,000 | 262 | 164 | 109 |

| 2" | 1.900 | 48.26 | 0.090 | 2.29 | 1.741 | 2.59 | 50,000 | n/a | 230 | 154 |

| 2-1/2" | 2.375 | 60.33 | 0.095 | 2.41 | 2.315 | 3.44 | 50,000 | n/a | 389 | 259 |

| 3" | 2.875 | 73.03 | 0.110 | 2.79 | 3.251 | 4.84 | 50,000 | n/a | 663 | 442 |

SS40®:

Allied Tube & Conduit has become the largest domestic manufacturer of galvanized steel fence framework. Allied's SS40® consistently outperforms Schedule 40 and pre-galvanized pipe products in areas of strength and corrosion resistance. SS40® is hot-dip galvanized and chromated by total immersion, followed by a clear organic coating. This coating minimizes oxidation, preserving a bright shiny appearance. The combined coatings of zinc, a conversion coating and clear organic top coat produce a "synergistic" effect that has greater corrosion resistance than the sum of the individual coatings. It all adds up to superior protection.

Product Benefits:

- Triple coating provides superior corrosion resistance

- All surfaces coated after fabrication

- Yield Strength of 50,000 psi minimum

- 33% stronger than Schedule 40, yet is 20% lighter

- Bright, shiny, maintenance-free exterior finish

- Conforms to Federal, State, and Industrial specifications

- Manufactured in the U.S.A.

- Nationwide distribution

Applications:

- Commercial and Industrial Applications

- Institutional Applications

- Correctional Facilities

- Military Installations

- Storage Facilities

- Highways

- Airports

Code Certifications:

- AASHTO M181-93

- Federal Specification RR-F-191/2D (Chain Link Fence Gates)

- Federal Specification RR-F-191/3D (Chain Link Fence Posts, Braces, Top Rails)

- Corps of Engineers CEGS-02831

- Department of the Navy NFGS-02831

- Department of Transportation Federal Aeronautics Administration AC 150/5370-10A Item F-162

- U.S. Department of Justice - Federal Bureau of Prisons

- ASTM Specifications F-1043-95

- American Institute of Architects (AIA) Master Spec

- Chain Link Fence Manufacturers Institute Product Manual

| Size (O.D.) | Decimal Equivalent | Pipe Wall Thickness | Weight | Minimum Yield | Max. Bending Moment | Calculated Loads | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | in. | mm | in. | mm | lb./ft. | kg/ft. | psi | lbs./in. | 10' Free | 4' Cantilever | 6' Cantilever |

| 1-3/8" | 1.315 | 33.40 | 0.104 | 2.64 | 1.35 | 2.01 | 50,000 | 5,555 | 185 | 116 | 77 |

| 1-5/8" | 1.660 | 42.16 | 0.111 | 2.82 | 1.84 | 2.74 | 50,000 | 9,805 | 327 | 204 | 136 |

| 2" | 1.900 | 48.26 | 0.120 | 3.05 | 2.28 | 3.39 | 50,000 | 14,050 | 468 | 293 | 195 |

| 2-1/2" | 2.375 | 60.33 | 0.130 | 3.30 | 3.12 | 4.64 | 50,000 | 24,405 | 814 | 508 | 339 | 3" | 2.875 | 70.03 | 0.160 | 4.06 | 4.64 | 6.90 | 50,000 | 43,890 | 1,463 | 914 | 610 | 3-1/2" | 3.500 | 88.90 | 0.160 | 4.06 | 5.71 | 8.50 | 50,000 | 67,040 | 2,235 | 1,397 | 931 | 4" | 4.000 | 101.60 | 0.160 | 4.06 | 6.56 | 9.76 | 50,000 | 89,095 | 2,970 | 1,856 | 1,237 |

Note: Specifications and descriptions are accurate as known at time of page creation and are subject to change without notice.

Chain Link Post Fittings:

We have highlighted some of the most common fittings below. Almost all of the fittings are available in steel and aluminum. The steel options are offered in galvanized and color coated. Please check out our comprehensive Chain Link Post Fittings Catalog for more options, finishes, and materials.

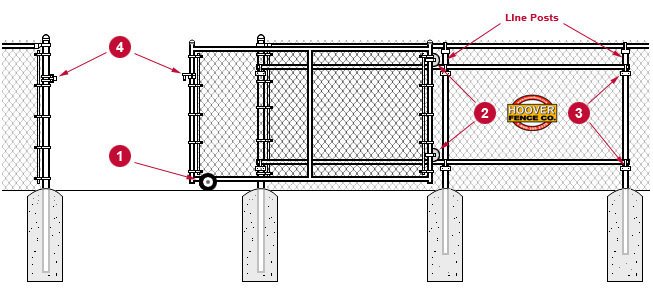

Common Terminal Post Fittings:

Typical Terminal Post Fitting Diagram

Post Caps - Post caps are used to cap the terminal posts on a fence project to create a clean professional finish and to also keep water and other debris from getting into the posts and prematurely rusting. Order (1) post cap for every terminal post on the project.

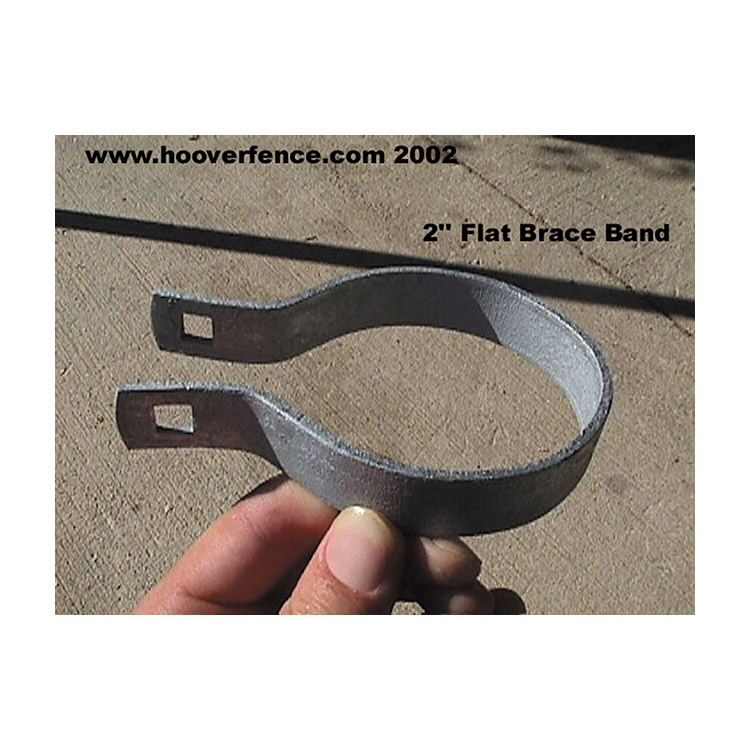

Brace Bands - Brace bands are used to attach rail end cups, barbed wire, and tension wire to terminal posts during installation. Brace Bands are available in both flat and beveled variations, the latter being for commercial applications. Order (1) for every rail, tension wire, or barbed wire hook-up, per termination.

Rail End Cups - Rail End Cups are used to terminate the horizontal pipe rails at the end or corner posts. We offer these fittings in both steel and aluminum, and in standard and combo configurations. Order (1) for every horizontal rail connection to a terminal post.

Tension Bars - Tension bars are used to terminate the chain link fabric at end or corner posts. They slide down in the fabric and provide a surface to attach the tension bands. Order (1) for every termination or change in direction of the fence.

Tension Bands - Tension bands are used to attach the chain link fabric to the terminal posts. To figure out the number of needed tension bands, take the height of the fence (ex. 6'), take 1 away from that number to get (5), and multiply that by the total number of tension bars on the fence project.

5/16" x 1-1/4" Carriage Bolts & Hex Nuts - Order (1) for every tension band or brace band connection needed on the project.

Truss Rods - If you are bracing an trussing the project, you will typically use one for every terminal location on the project. Alternate methods utilize two per termination in an 'X' pattern.

Truss Rod Tighteners - These are bolted to the terminal posts using brace bands and provide a rigid connection point for the truss rod. Order (1) for every truss rod on the project.

End Rail Clamps - Sometimes when a horizontal rail is added to a fence (besides the top rail), customers will use an End Rail Clamp instead of a brace band rail end cup combination. If this is the case, you can use this on end post connections, but corner connections would require the rails to be on different planes, which is less than ideal and not recommended.

5/16" or 3/8" Carriage Bolts - Order (1) for every end rail clamp on the project. Size required varies per clamp and fasteners need to be figured separately.

Common Line Post Fittings:

Typical Line Post Fitting Diagram

Loop Cap - Loop Caps serve a dual purpose, not only do they cap the line posts off, they also provide a secure location for the top rail on the fence. The 'Loop' is offset to one side of the cap, make sure that you put the loop closest to the side that will have the chain link fabric on it. Order (1) for every line post on the project.

Barb Wire Arm - If you have barbed wire on the project then these are utilized in lieu of the loop caps. They cap the posts, provide a secure attachment of the top rail, and a 'Z' shaped notch to hold the barbed wire strands. Order (1) per line post on the project.

Brace Band - If you are bracing and trussing the fence, then there is one brace band required for the first line post after every termination. Typically the same number as the tension bars on the project.

Rail End Cup - Order (1) for every brace band required if you are bracing and trussing the terminal posts.

5/16" x 1-1/4" Carriage Bolt & Hex Nut - Order (1) for every brace band and rail end cup required if bracing and trussing the terminal posts.

Line Rail Clamp - These clamps provide a secure way to fasten horizontal rails to the line posts. Order (1) for every horizontal rail connection (besides the top rail which passes through the loop cap or barb wire arm).

5/16" or 3/8" Carriage Bolts - Order (2) for every line rail clamp on the project. Size required varies per clamp and fasteners need to be figured separately.

Top Rail Sleeve - These sleeves are used to connect two pieces of horizontal rail. Order (1) for every splice of top rail, unless you have a swaged end.

Chain Link Gates:

The most common chain link gates are swing gates, in both single and double configurations. We also offer cantilever slide gates and rolling gates. We carry three grades - Residential, Commercial, and Industrial. The swing gates are available in both aluminum and steel. Steel gates are available in galvanized and color coated finishes.

Residential Swing Gates:

Single Residential Swing Gate

Double Residential Swing Gate

Our Residential Chain Link Single and Double Swing Gates feature a welded .065 wall gate frame, and fabric of your choice. The corners are notched and welded for a strong and aesthetic finish. We then clean and paint the welded joints for a professional finish. The chain link fabric is attached to the gate uprights with tension bars and gate clips, and aluminum tie wires attach the fabric at all horizontal rail connections. Our gates ship assembled, and do not include hardware.

Commercial Swing Gates:

Single Commercial Swing Gate

Double Commercial Swing Gate

Our Commercial Chain Link Single and Double Swing Gates feature a welded 1-5/8" HF20 gate frame stretched with 9 ga.fabric. The corners are notched and welded for a strong and aesthetic finish. We then clean and paint the welded joints for a professional finish. The chain link fabric is attached to the gate uprights with tension bars and tension bands, and aluminum tie wires attach the fabric at all horizontal rail connections. Our gates ship assembled, and do not include hardware.

Industrial Swing Gates:

Single Industrial Swing Gate

Double Industrial Swing Gate

Our Industrial Chain Link Single Swing Gates feature a robust welded 2" HF40 gate frame stretched with 9 ga. fabric. The corners are notched and welded for a strong and aesthetic finish. We then clean and paint the welded joints for a professional finish. The chain link fabric is attached to the gate uprights with tension bars and tension bands, and aluminum tie wires attach the fabric at all horizontal rail connections. Our gates ship assembled, and do not include hardware.

Commercial Rolling Gates:

Read More: Rolling Gate System Overview

Chain Link Rolling Gate

Our Commercial Chain Link Rolling Gates are a great solution for securing openings while minimizing the footprint of the gate. This style of gate slides parallel with the fence line using a track and wheel system. Gates are 6" shorter than the height shown in order to make room for the bottom wheel, while matching up with the fence height. Gates are also built 12" longer than the width shown to allow the whole opening to be closed off. This extra length pushes the back edge of the gate past the terminal post and allows the necessary room for the rear wheels. This style of gate does not require a large counterbalance like it's Cantilever Slide Gate counterpart, which would be recommended if a larger opening is required, or if the gate is to be automated.

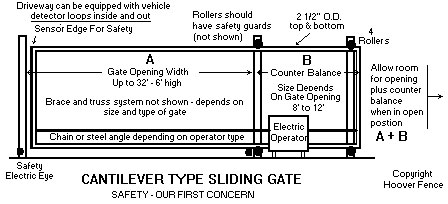

Cantilever Slide Gates:

Read More: Cantilever Gate System Overview | How to Install Chain Link Cantilever Gates

Chain Link Cantilever Gate

Advantages to cantilever slide gates over other styles are numerous. Since no part of the gate comes in contact directly or indirectly with the ground, cantilever slide gates are easy to automate with gate operators. Gates can often very easily be installed perfectly level. Proper design, fabrication, and installation of a cantilever slide gate will reduce friction during operation and prolong the life of a gate operator. Gate hardware systems from a quality fence supply source will provide smooth operation and low maintenance. A cantilever slide gate features the ability to slide along the fence line without requiring any lateral space as swing type gates demand.

Aluminum Single Track Slide Gate:

Single Track Slide Gate

Hoover Fence Company's aluminum slide gates are of the highest quality available in the fencing industry. Heavy duty high quality slide gate track and stainless steel gate trolleys provide for smooth and effortless operations during open and close of gates. Aluminum slides gates are built with a single track for single gate openings up to 30' wide. 60' wide gate openings can be achieved by installing a double slide gate. Gate finish sizes can be as much as 50% more than the opening to allow for proper counterbalance. Single track aluminum gates typical use two 4" O.D. posts for mounting and one 4" latch post.

Aluminum Double Track Slide Gate:

Double Track Slide Gate

Hoover Fence Company's aluminum slide gates are of the highest quality available in the fencing industry. Heavy duty high quality slide gate track and stainless steel gate trolleys provide for smooth and effortless operations during open and close of gates. Aluminum double track slide gates are used for gate opening widths greater than 30' and up to 40'. An 80' gate width opening can be accomplished by installing one of our double slide gate systems. Gate finish sizes can be as much as 50% more than the opening to allow for proper counterbalance.

Gate Fittings:

We have highlighted some of the most common fittings below. Almost all of the fittings are available in steel and aluminum. The steel options are offered in galvanized and color coated. Please check out our comprehensive Chain Link Gate Fittings Catalog for more options, finishes, and materials.

Residential Swing Gate Fittings:

Male Strap Hinges - Residential chain link swing gates are hung by 'strap hinges' which is an assembly consisting of (1) Male Strap Hinge, (1) Female Strap Hinge, and (2) Carriage Bolts w/ Nuts. Order (2) male strap hinges per gate along with (2) carriage bolts and hex nuts per gate leaf.

Female Strap Hinges - Residential chain link swing gates are hung by 'strap hinges' which is an assembly consisting of (1) Male Strap Hinge, (1) Female Strap Hinge, and (2) Carriage Bolts w/ Nuts. Order (2) female strap hinges per gate along with (2) carriage bolts and hex nuts per gate leaf.

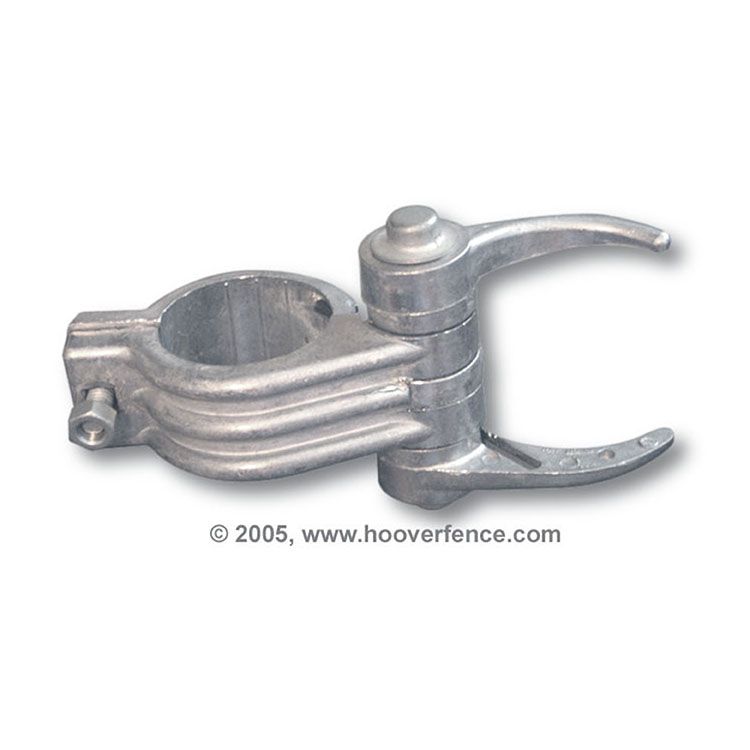

Fork Clamp - The most common latch for residential chain link swing gates is the 'fork latch'. This is actually a latch assembly that consists of (1) Fork Clamp (sized to the gate frame), (1) Fork (sized to the latch post diameter), and (2) 5/16" x 1-1/4" carriage bolts and hex nuts. Order (1) fork clamp per single gate on your fence project.

Fork - The most common latch for residential chain link swing gates is the 'fork latch'. This is actually a latch assembly that consists of (1) Fork Clamp (sized to the gate frame), (1) Fork (sized to the latch post diameter), and (2) 5/16" x 1-1/4" carriage bolts and hex nuts. Order (1) fork per single gate on your fence project.

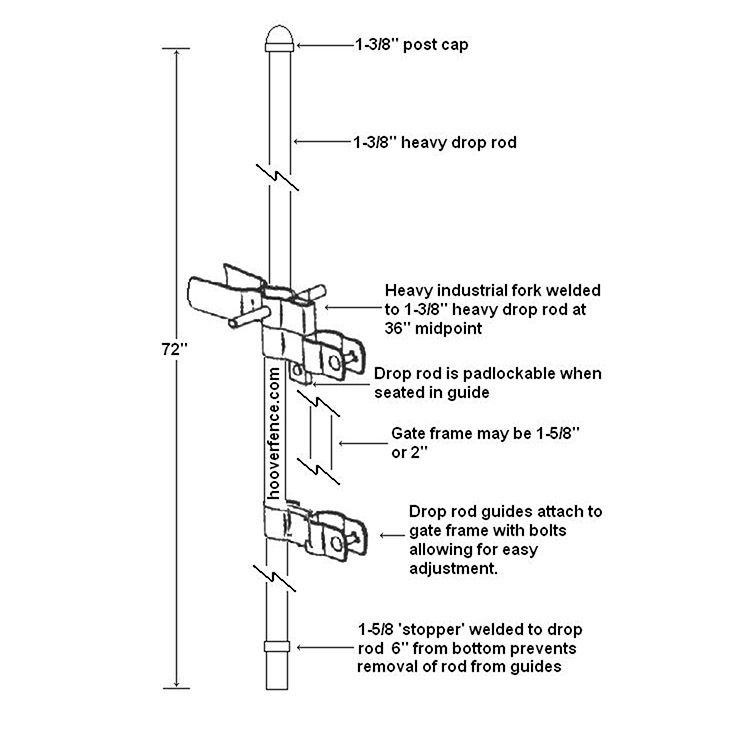

Residential Drop Rod Assembly - If you have double gates on your project, you will want to order (1) Residential Drop Rod Assembly per double gate on your project. This drop rod is designed to bolt and latch between two 1-3/8" diameter gate frames.

Residential Gate Closer - These residential gate closers are designed to bolt to the hinge post, and the 'fingers' wrap around the gate frame. These closers are designed to be used in addition to male and female strap hinges and allow the gate to be closed if the gate is swung in or out. You can pair it with a Butterfly Latch for a simple self closing swing gate.

Commercial & Industrial Swing Gate Fittings:

Butt/Box Hinges - Butt or Box Hinges as they are commonly referred to, are a very common choice for hanging commercial or industrial chain link swing gates. The unique design allows the hinges to fit either 1-5/8" or 2" round gate frames, simply by flipping over the collar on the gate side of the hinge. This style of hinge is available in bolt malleable and pressed steel construction. Most applications require (2) per gate leaf on the project, though some large gates may require three per leaf.

180 Degree Adapter - This fittings is designed to be used with Butt Hinges, or Bulldog hinges, and allows for a 180° swing of the gates - that is to say that you can swing the gate all the way back along the fence line. If you are using this on your project, order (1) for every hinge.

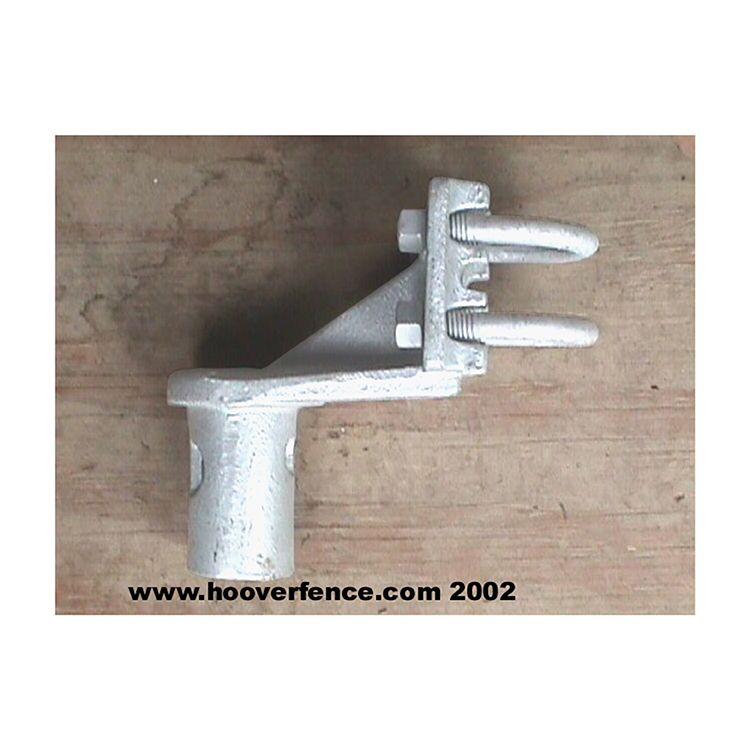

Malleable Drop Fork Latch - This assembly is commonly used to latch single gates on commercial or industrial fence project. The latches are designed for 1-5/8" or 2" gate frames, and post sizes of 2-1/2", 3", and 4" round. Order (1) per single gate on the project.

Fulcrum Latch - The Fulcrum Style latch is a heavy duty latch designed for more security on your commercial or industrial chain link swing gates. There are options for both single and double swing gates. The double latch eliminates the need for an additional drop rod. Order (1) per single or double gate on your project.

Commercial Drop Rod - This heavy duty assembly is for use with commercial or industrial chain link double swing gates. They are designed to mount and latch between two 1-5/8" or 2" round gate frames. Order (1) per double gate on your project.

Rolling Gate Fittings:

Wheel Carriers - The function of the wheel carriers, single or double, is to hold up the weight of the latch side of the gate. They also keep the gate lined up with the latch post. Most simply bolt on, however consider tack welding part of the fitting to better secure the fitting. Order (1) per rolling gate on your project.

Rear Wheels - The function of the rear wheel is twofold; it both holds the rear of the gate off the ground and keeps the gate on the track at the same time. Rear wheels bolt to the upright of the gate frame using rear wheel brackets. There is a small steel plate mounted to the rear wheel which holds the gate on the track. All rear wheels will roll on a 1-5/8" track which is a typical size of tubing used for top rail, mid rail, and bottom rail. Typically you will want to order (2) per rolling gate on your project.

Pipe Track Brackets - Pipe track brackets are used to mount the track to the posts. They are available in different sizes and shapes for different mounting applications. They are cast in such a way that allows you to connect 1-5/8" track on each end to continue the track to infinity. The same part is used to terminate the track; simply cut off the swedged piece for a trimmed look. Typically you will order (2) brackets per post that you are attaching the pipe track to.

Pipe Track Brackets - As with most latches, rolling gate latches are used to secure and lock a fenced in area or driveway. These are also available in a few different styles. Order (1) per rolling gate on your project.

Cantilever Slide Gate Fittings:

Cantilever Gate Rollers - Cantilever gate rollers are available with steel or nylon rollers. We carry rollers for a variety of post and gate frame sizes in both square and round profiles. Typical cantilever gate installations require (4) rollers per gate. Always order cantilever roller covers to protect the pinch points.

Cantilever Roller Covers - Cantilever roller covers are available to fit all cantilever rollers that we carry. We recommend ordering a cover for every cantilever roller that is used on the project. The rollers protect the pinch points between the cantilever roller and gate frame.

Cantilever Gate Latch Assembly - The cantilever gate latch shown is made up of the latch and latch piece. The latch is mounted to the latch post and remains stationary, while the latch piece is mounted to the gate frame. Order (1) Latch and (1) Latch Piece for each cantilever on the project.

Internal Track Slide Gate Fittings:

Trolley Hanger Brackets - The trolley hanger brackets are used to mount the internal track slide gate trolleys to the posts. In this gate system, the trolleys are stationary and the gates move. Typically you will order (1) trolley hangers for each post used to hang the gates.

Slide Gate Trolleys - Slide Gate Trolleys are used in the internal track slide gate system. These trolleys are available in a variety of configurations and they slide inside the track that is built into the gate. Order (1) for every trolley hanger bracket on the project.

Bottom Guide Rollers - Bottom guide rollers are used to keep the bottom of the gate from kicking out on a typical internal track slide gate. Order (1) per supporting post on the slide gate project.

Gate Stop Brackets - These brackets are used to keep the gate from sliding off the track when installing the internal track slide gate system.

Slide Gate Latches - These latches are designed specifically for the internal track slide gates, and compensate for the offset from the trolley hardware. Order (1) per gate on the project.

Chain Link Wires and Ties:

The last component in the chain link fence system are comprised of tie wires, tension wire, barbed wire, and hog rings. These are used to provide added security and also to connect all the other components together.

Barbed Wire:

Barbed wire is most commonly used to increase security on commercial or industrial chain link fence applications. Most projects will ask for 3-wires of barbed wire, though some may ask for 6, which creates a 'V' shape on top of the fence. We offer Barbed Wire is a variety of finishes and materials. Some agricultural applications will require barbed wire as well. Barbed Wire ships in 1,320' rolls (1/4 mile). The only version that doesn't come in this length is the all aluminum barbed wire, which comes in 1,000' rolls.

Tension Wire:

Tension wire is commonly used as bottom wire on a fence, though it can be used in lieu of top rail on large or budget conscious projects. Tension wire is available in a variety of finishes and materials. Most variations are available by the foot or in full 1,000' rolls.

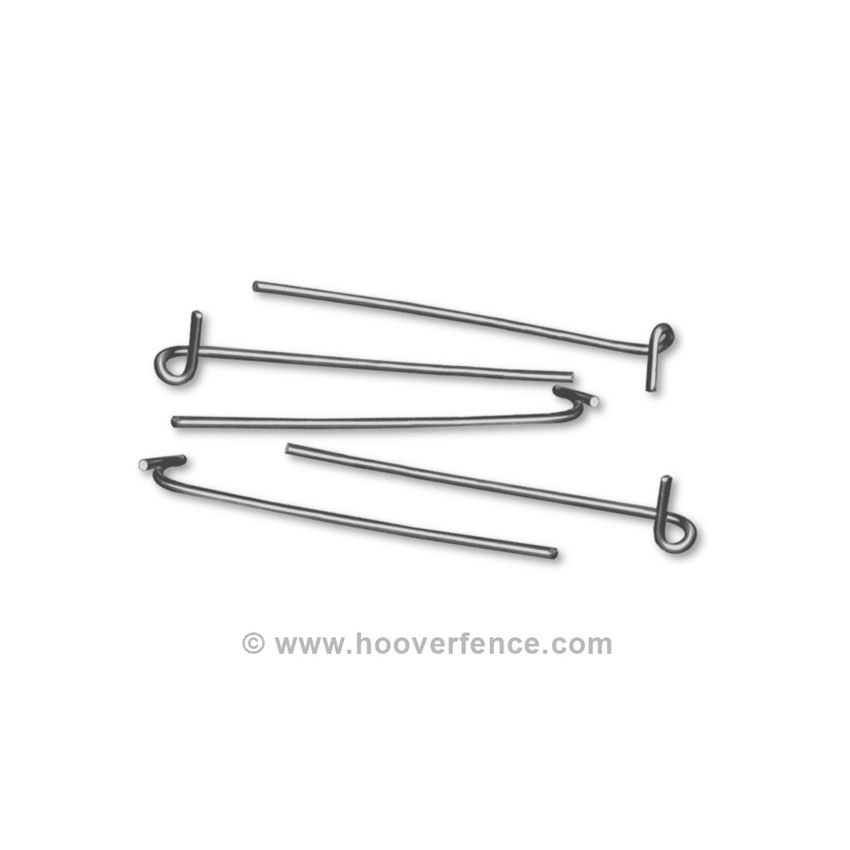

Tie Wires:

Tie wires are used to fasten the chain link fabric to the posts, top rails, brace rails, and gate frames, on a chain link fence project. Tie wire spacing is typically 2 foot on horizontal rails and every foot on line posts. Ties are sold in a variety of material and finishes and typically ship in bags of 100. We also carry preformed ties that are tightened using special drill powered attachments.

Hog Rings:

Hog rings are used to attach the chain link fabric to the tension wire on the project. You typically space the hog rings every two feet. Our hog rings are available in steel and aluminum, and in colored finishes. We also carry special tools that use collated hog rings.